UME

Fluid Flow Laboratories

About Us

One of the main duties of UME is to establish and make available the national primary standards in accordance with the country's needs. In parallel with this mission, the Fluid Flow Laboratories expand the capacities of existing systems or establish new systems when necessary, based on developments within the country and the demands of stakeholders. In addition to calibration and testing activities, the laboratories also strive to meet non-calibration-related measurement, system development, and consultancy requests from industry as much as possible. Furthermore, they actively participate in national and international projects related to flow measurement.

Areas of Activity and Services

Water Flow Laboratory

UME Water Flow Laboratory was established to provide water meter measurement and calibration services to the national industry. The capacity of the primary level reference systems in the laboratory covers the flow range from 0.01 m3/h to 2000 m3/h and the measurement uncertainty is below % 0.06.

The water supply system in the laboratory is made from the 300 m3 pool located inside the laboratory or from the 50 m3, 15 m3 and 5 m3 constant level tanks located in the 35 m high water tower located outside the laboratory. There are many frequency controlled pumps for water supply to the measurement lines. These pumps have maximum flow rates ranging from 20 m3/h to 1000 m3/h and are connected to the measurement lines to supply the system directly or through the water tower tanks.

For measurements where water temperature needs to be controlled (e.g. hot water meters), the laboratory also has two separate tanks with water temperature control, operating independently from the water pool and supplying hot or cold water to the measurement line. The Water Flow Laboratory has a total of 15 metering lines with diameters ranging from DN-250 to DN-5. This measurement consists of stainless steel pipes and is equipped with automatic valves, different types of reference flow meters (Coriolis, magnetic and ultrasonic) and temperature/pressure sensors. Gravimetric based primary level systems are used as reference in the laboratory. There are four of these systems, all designed and manufactured in Turkey. The maximum weighing capacities of the systems are 10 kg, 1 ton, 5 tons and 30 tons. All of the systems are used in flying start and stop mode. Apart from these, there is 1 Piston Prover volumetric flow measurement system.

All equipment and devices in the Water Flow Laboratory are controlled by a PLC system and measurements are made via computer. The measurements that can be made in the laboratory are listed below.

Test and Measurement Services

- Calibration and testing of water meters

- Testing of hot and cold water meters

- Valve, armature and pump experiments

Technical Hardware and Equipment

- Four primary levels (10kg, 1 ton, 5 ton and 30 ton capacity) maximum 3000 m3Gravimetric water flow rate standard at /h flow rate

- Coriolis, magnetic, turbine and ultrasonic flow meters in various diameters and flow rates.

- 100 m between 5 and 70 °C3/h maximum hot/cold flow measurement lines.

- Measuring lines of various diameters from DN5 to DN600.

- 11 pumps operating at various pressures and flow rates.

- 35 m high water tower

- 200 tons capacity water pool

Gas Flow Laboratory

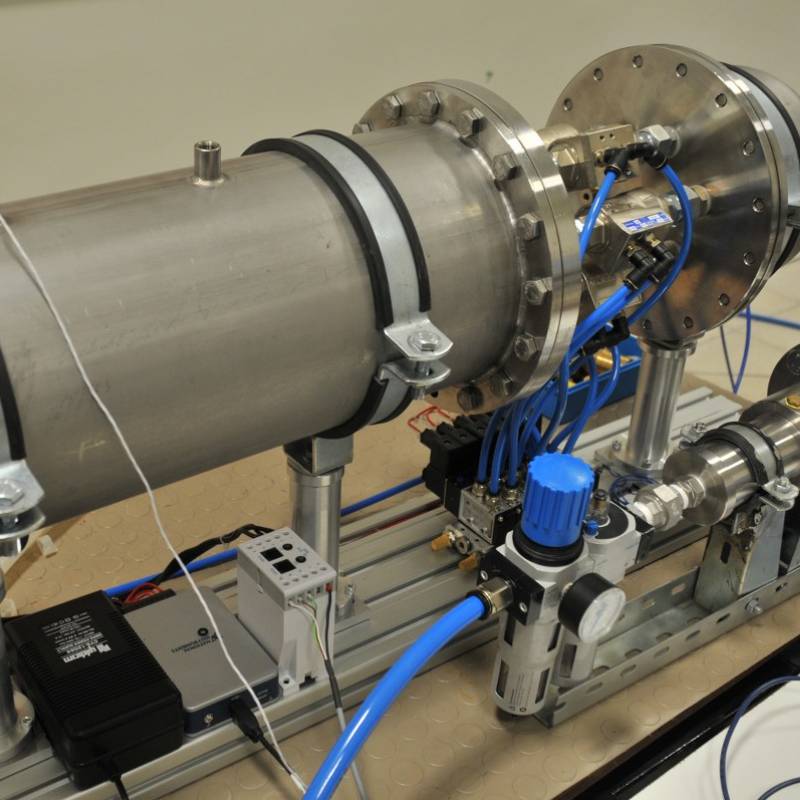

The large number of gas flow reference devices in the Gas Flow Laboratory covers a wide range of flow rates from 1 ccm to 14100 m3/h. Calibrations and tests of different types of gas meters and flow meters can be performed in the laboratory. The primary level reference system in the laboratory is the Bell-Prover device. This device covers the flow range from 0.2 m3/h to 100 m3/h under atmospheric pressure conditions with an uncertainty value of % 0.2. The main components of the Bell-prover consist of a bell-shaped cylinder, a counterweight that stabilizes the weight of the cylinder and a rotary encoder that measures the cylinder movement.

As the air fills the cylinder, the displacement of the bell moving upward with the gas pressure against time is measured by means of a rotary encoder and the volume and flow rate value is obtained. Bell prover is traceable from UME Dimensional, Pressure, Time-Frequency and Temperature Laboratories. The traceability of all other reference devices in the laboratory is provided from the Bell-Prover device.

Other reference devices used for low gas flow rates are wet gas meters and dry piston devices. Wet gas meters are used in the flow range of 2 l/h - 18 000 l/h with an uncertainty of % 0,25 and dry piston meters are used in the flow range of 1 ccm - 50 LPM with an uncertainty of % 0,25.

New measurement instruments are being developed at the UME Gas Flow Laboratory. The sonic nozzle bank gas flow measurement and calibration system is the latest example of laboratory-developed instrumentation. It operates with a maximum of six nozzles and each nozzle flow range is controlled by the inlet air pressure and the diameter of the nozzle. The sonic nozzle system is able to provide a very stable level of continuous constant air flow up to a flow rate of 120 m3/h with an uncertainty of % 0.21. The whole system is controlled by computer. Sonic nozzle bank calibration and test equipment can be produced according to customer needs and requests, especially for natural gas distributors and gas meter manufacturers.

In the laboratory, a large number of turbine meters are used as reference instruments under atmospheric pressure conditions. With these turbine meters and test systems, UME Gas Flow Laboratory provides testing and calibration services in the following flow ranges.

Test and Calibration Values

- % in the flow range 10 m3/h - 6600 m3/h with an uncertainty of 0.45

- % up to 14,100 m3/h flow rate with 0.80 uncertainty

Technical Hardware and Equipment

- 0.2 to 100 m3Bell-prover primary level standard with measuring capacity of /h.

- Secondary level flow standards of various numbers and types (dry piston, sonic nozzle, mass, turbine meter and wet gas meter) ranging from 0.02 ccm to 19,500 m3/h.

- Precise pressure and flow regulators.

- Low pressure fans of various numbers and capacities and one high pressure fan.

Air Velocity Laboratory

In the UME Air Velocity Laboratory, calibration and testing services of different types of anemometers and air velocity meters in the air velocity range of 0.5 m/s to 40 m/s are provided by means of an open wind tunnel with an Eiffel-type 315 mm nozzle outlet.

A two-dimensional Laser Doppler Anemometer (LDA) is used as the main reference in the laboratory. A rotating disk device has been developed in the laboratory for the primary use of this instrument. This device basically consists of a glass wheel that rotates at constant speeds. The LDA device is calibrated by performing velocity measurements on the top surface of the wheel. Since the surface (or linear) velocity of the wheel depends on the angular velocity and wheel diameter, the traceability of the LDA device is provided by the UME Dimensional and Time-Frequency Laboratory. In most of the calibrations and tests performed in the laboratory, the pitot tube device is used as a reference.

Technical Hardware and Equipment

- Eifel-type wind tunnel operating in the measurement range of 0.5 to 40 m/s.

- Primary level laser doppler anemometer (LDA) measurement system.

- Rotating disk system for calibrations of LDA systems.

- Pitot tube speed measurement systems

- Ortam Koşulları: Her laboratuvar için sıcaklık 23±1 °C ve bağıl nem %45±10 değeridir.

Services Provided

Calibration / Testing Services

Training Services

Consulting Services

MECHANICS GROUP

Projects and Collaborations

- FP7 EMRP Project, HLT07 MeDD Metrology for Drug Delivery (2012-2015)

- FP7 EMRP Project, METEOMET-Metrology for Meteorology (2011-2014)

For more informationContact Us

Email: ume@tubitak.gov.tr

Phone: 0 (262) 679 5000