UME

Medical Metrology Laboratory

About Us

Upon the conclusion of studies conducted under the “Medical Metrology Feasibility” Project, the Medical Metrology Laboratory of TUBITAK UME was formally established by decision of the TUBITAK Science Board on December 6, 2014.

The main objective of UME Medical Metrology Laboratory is to establish the traceability of measurement quantities relevant to medicine, to integrate the measurement quantities into the international metrology system through international comparisons and to ensure measurement unity by disseminating traceability to lower level laboratories within the country or abroad through calibration, measurement and test services. The other objective of the laboratory activities is to produce research projects in line with national priorities and the stakeholder demands. In this context, the laboratory has participated as a partner in research projects conducted within the European Metrology Research Programme (EMRP) and European Metrology Programme for Innovation and Research (EMPIR) under EURAMET.

Areas of Activity and Services

Main Service Areas

- Ensuring measurement traceability and reliability of devices used in the field of health

- Design and manufacture of calibrators for medical devices

- Establishing systems and producing projects for applications of ultrasonic techniques in the field of health

- Performance testing of hearing aids and headphones

- Phantom (tissue-like material) production for preclinical research

- Hands-on training for calibration professionals

Instrument Construction, Calibration and Measurement Services

- Patient Simulator Calibration System

- NIBP Simulator Calibration System

- Defibrillator/Pacer Analyzer Calibration System

- Electrical Safety Analyzer Calibration System

- Pulse-Oximeter (SpO2) Analyzer Calibration System

- Infusion Pump Analyzer Calibration System

- Gas Flow Analyzer Calibration System

- Electrocautery/Electro-Surgery Analyzer Calibration System

- Hearing Aid Performance Testing System

- Calibration of the Filtered Mouthpiece of a Spirometer

- Measurement Systems for Ultrasonic Applications in Healthcare

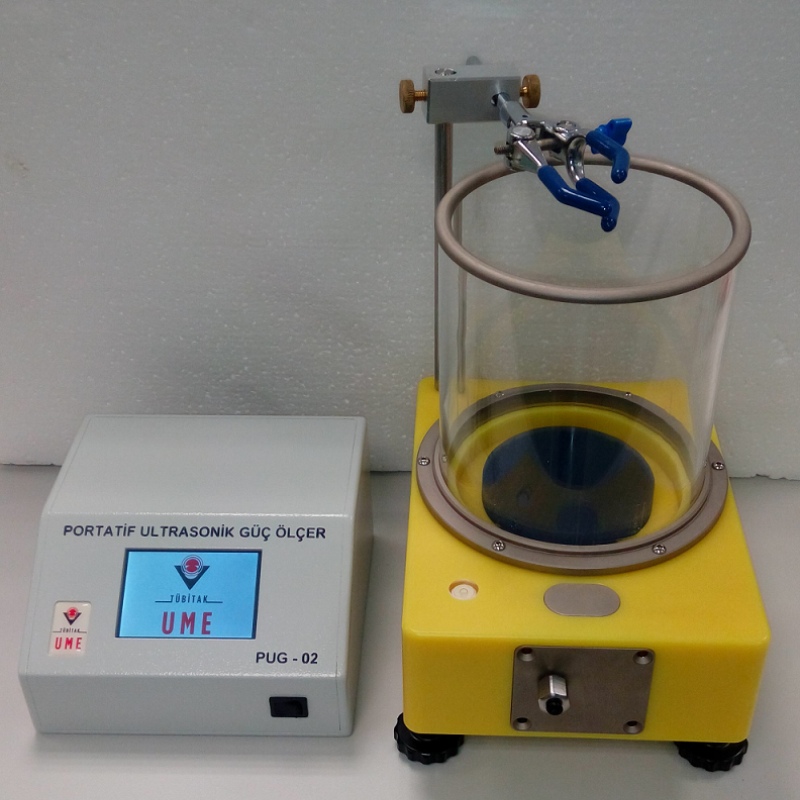

- Portable Ultrasonic Power Meter (PUG) Device Production

- Infrared Ear Thermometer (IRET) Measurement System Device Production

- Ultrasonic Imaging System Phantom Production

- Ultrasonic Probe Production for Imaging and Therapeutic Purposes

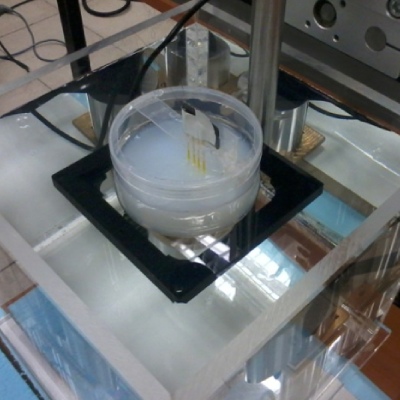

Primary Ultrasonic Power Standard

Currently, the operating region of the national standard covers a frequency range of 1 MHz - 15 MHz and a power range of 10 mW-150 W. With the radiation force balance installed in the laboratory, it is possible to measure the output power of High Intensity Focused Ultrasonic Transducers, which are widely used in medicine, up to 150 W. Systems have been established and projects are being produced for the applications of ultrasonic techniques in the field of health.

- Determination of output power of ultrasonic diagnostic and treatment devices,

- Ultrasonic transducer field characterization.

In addition, systems for performance testing of hearing aids and headphones have been established and services are also provided in this field.

Services Provided

Calibration / Testing Services

Training Services

Consulting Services

Technical Hardware and Equipment

Environment Conditions

| Environmental Parameter | Must-Have Values | Tolerances |

|---|---|---|

| Temperature | 23,0 ° C | ± 3,0 |

| Relative Humidity | % 45,0 | ± 15,0 |

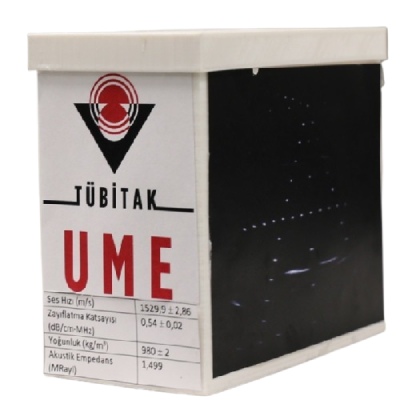

Phantom Product

| Technical Specifications | ||

|---|---|---|

| MANUFACTURER | TUBITAK UME | |

| MODEL | FANTOM-1 | |

| YEAR OF PRODUCTION | 2019 | |

| DIMENSIONS(W x L x H x H) | 76 mm x 144 mm x 123 mm | |

| FANTOM TYPE | Distance Verification Phantom | |

| PHANTOM MATERIAL | Zerdine Phantom | |

| MEASUREMENT POSITION | Vertical | |

| SPEED OF SOUND | 1529.9 ± 2.86 m/s | |

| ATTENUATION COEFFICIENT | 0.54 ± 0.02 (dB/cm.MHz) | |

| DENSITY | 980 ± 2 (kg/m³) | |

| ACOUSTIC IMPEDANCE | 1,499 (MRayl) | |

| PORTABILITY | Portable Stationary Platform System | |

| COMMERCIALIZATION | Please contact the TÜBİTAK Technology Transfer Office. | |

Quartz Product

| Technical Specifications | ||

|---|---|---|

| MANUFACTURER | TUBITAK UME | |

| MODEL | 1.0 | |

| YEAR OF PRODUCTION | 2019 | |

|

OUTER DIMENSIONS ARMS IN FULL OUTSTRETCHED POSITION |

600 mm x 300 mm x 155 mm | |

|

OUTER DIMENSIONS ARMS IN CLOSED POSITION |

Body Diameter (150 mm) x Height (155 mm) | |

| SOFTWARE | TUBITAK UME | |

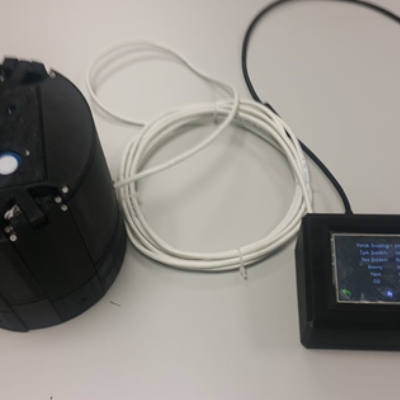

Prop Product

| Technical Specifications | ||

|---|---|---|

| MANUFACTURER | TUBITAK UME | |

| MODEL | 1.0 | |

| YEAR OF PRODUCTION | 2019 | |

| OUTER DIMENSIONS | 22.1 mm x 14.4 mm x 10.5 mm | |

| DISPLAY SCREEN | TFT | |

| SOFTWARE | TUBITAK UME | |

PHYSICS GROUP

Projects and Collaborations

- FP7 EMRP Project, Universal Ear Simulator and Metrology for the Detection of Inaudible Sound (2012 - 2015),

- FP7 EMRP Project, Metrology for Therapeutic Ultrasonics (2012 - 2015),

- Internally Supported Project - Reducing the Spread of Virus Project (COVID-19, SARS, MERS, etc.) - VirYAP (2020 -2022)

- Externally Funded Project (EMPIR 2018) - Combined Radiotherapy with Hyperthermia - Adaptation of Biological Equivalent Dose Concept - RaCHy (2019 - 2022)

- Portable Ultrasonic Wattmeter Production

- Production of single and multiple ultrasonic probes in different sizes and shapes

- Infrared Ear Thermometers (IRET) Calibrators, Laboratory and Portable Type

- Ultrasonic Imaging Studies

- Ultrasonic Pressure Field Characterizations of Props

- Ultrasonic Imaging Phantom Production

- Calibrator Calibrator

- Multichannel Temperature Measuring Instrument

- RF Power Meter

- Quartz Calibrator

- Patent Works (Portable Ultrasonic Wattmeter, Portable Type Infrared Ear Thermometers (IRET) Calibrator, Baby Incubator Calibrator)

- Commercialization Studies (Portable Ultrasonic Wattmeter, Laboratory Type Infrared Ear Thermometers (IRET) Calibrator and Cavities, Portable Type Infrared Ear Thermometers (IRET) Calibrator, Ultrasonic Imaging Phantom)

For more informationContact Us

Email: ume@tubitak.gov.tr

Phone: 0 (262) 679 5000